at productronica

Hall A2, Stand 159

Your specialist for

polymer materials.

WERNER WIRTH provides protective coatings,

casting resins, adhesives and thermoplastics

for electronic component protection.

Your specialist for

polymer materials.

WERNER WIRTH provides protective coatings,

casting resins, adhesives and thermoplastics

for electronic component protection.

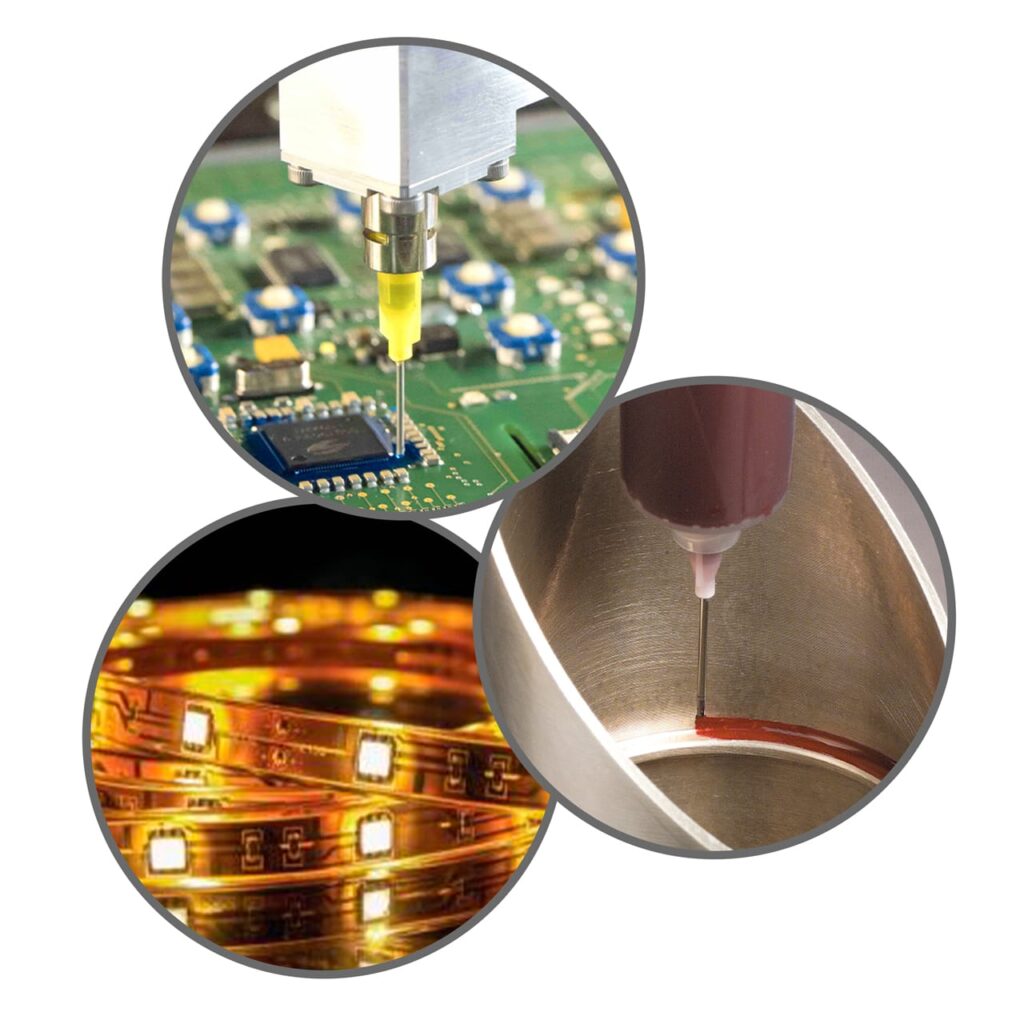

The most important ingredients for durable component protection for your electronics

Selecting the best polymer materials is essential in ensuring that connections function properly and components are permanently protected in production and operation. Are you looking for protective coatings for conformal coating, thermoplastics for hotmelt moulding, casting resins for potting or adhesives for bonding? You have come to the right place at WERNER WIRTH. Reliable electronic component protection under extreme conditions and environmental influences is one of our core strengths.

Whether you need to protect sensitive electronics inside a component from external influences or you need materials for a component protection process: we have many years of experience in this field to know which materials have the right effect and need to be used when, how, where and why. And we have or will find the right individual solution for your challenges too.

Talk to us and discover first-hand how we think in an integrated way and how comprehensive our expertise is, as it flows into every personal consultation.

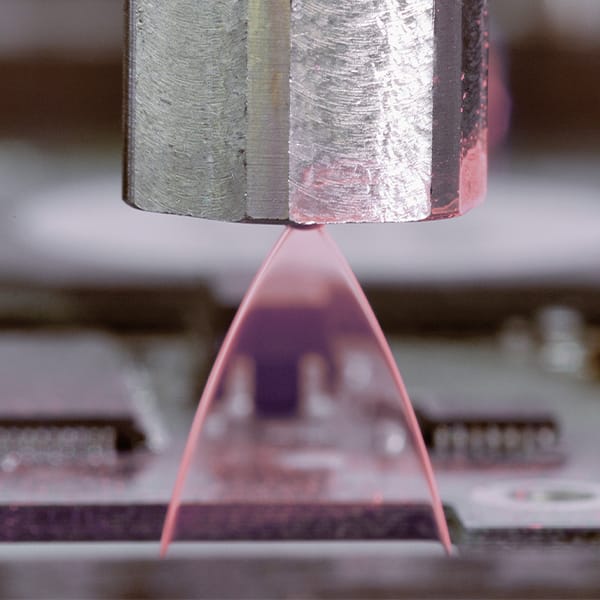

Conformal coating / Printed circuit board coating:

WERNER WIRTH provides the ideal protection for your highly sensitive PCB assemblies – protecting them against factors such as moisture, dust, UV light or acids: open or closed, transparent or opaque, suitable for any temperature and individually customised. Components partially coated with thin film or fully coated, sun-, optical- and solvent-protected components: when choosing the right material, you can rely on WERNER WIRTH.

As an experienced supplier of connection technology and component protection solutions, we have extensive expertise and offer a wide range of protective paints and coatings with different viscosities. And if you can’t find what you need off the peg, we will develop and produce it individually for you and your project. We provide precisely engineered coating materials that harden in exact times, run off precisely as calculated after the dip, and are later as long-lasting in use as your project’s environment requires.

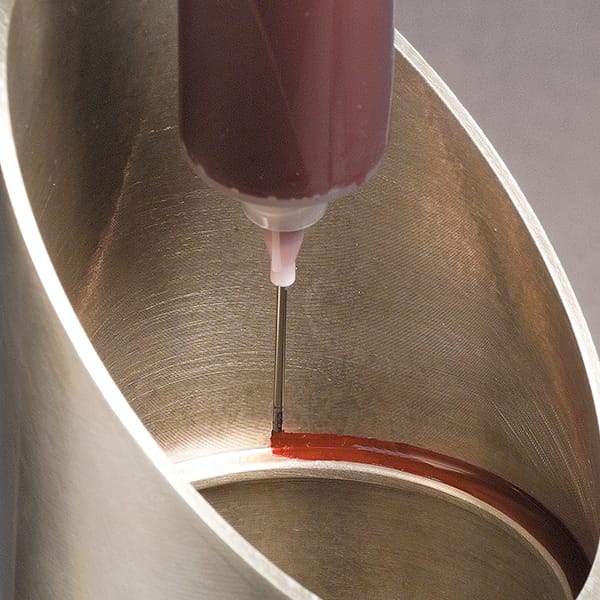

Potting / casting resin potting:

Cast resin potting protects against external influences such as extreme environmental conditions, provides fire protection, prevents pirating and also offers a housing function. We understand all these options and the associated requirements very well, and have the expertise and experience to recommend proven and economical casting resins for potting entire assemblies.

Durability tailored to your product requirements: one- and two-component potting compounds, polyurethanes and polyolefins, silicones and epoxy resins. Please also take advantage of performing a quick test run in our working lab as well as our many years of experience, which makes many tests superfluous.

Bonding:

If you are looking for reliable and durable connections to and on PCBs, we are completely in our element. This technology blurs the boundaries between connection technology and component protection – and we are masters of both. You can draw on our many years of experience to find out how liquid an adhesive can or must be, whether it should conduct or insulate, and whether a component should be underfilled or glop-top – or whether you should be able to see through it (optical bonding).

We look forward to discussing the advantages of each adhesive with you – from polyurethane which has a wide range of applications, to hard epoxy resins with very low coefficients of expansion or relatively soft silicones which are flexible from -50°C to 200°C, to versatile instant and super adhesives based on cyanoacrylates.

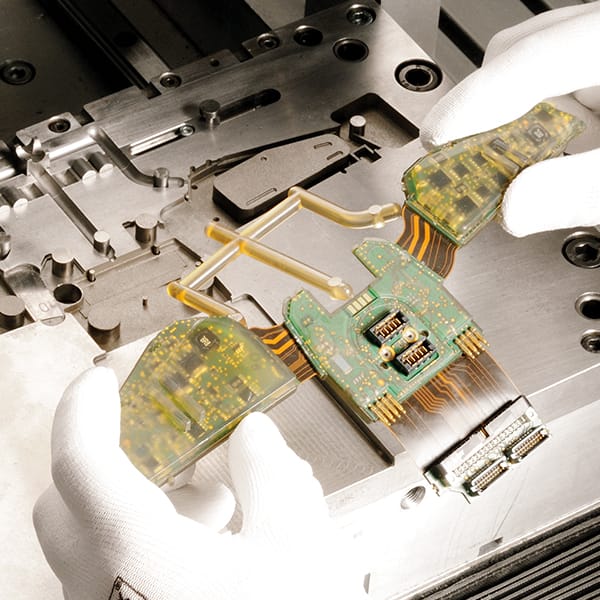

Hotmelt moulding / potting materials:

There are many areas of application: from sealing to encasing or shaping to housing. Therefore, finding the right potting material is an art in itself. Hotmelt moulding machines work at relatively low temperatures and with much lower injection pressure than normal plastic injection moulding. This protects the components and allows the thermoplastics to cure quickly. This is an advantage and a material challenge at the same time: the short cooling times mean that there are only a few seconds to completely enclose even the most delicate components, not to leave any cavities and to leave the machine without distortion. Our polyamides and polyesters are perfect for this.

Trust in WERNER WIRTH’s extensive consulting expertise and many years of experience when searching for the right material for top results at cost-effective prices.

Polymer materials: the perfect materials for long-lasting electronic innovations.

Protective coatings:

We recommend the BECTRON® range from Elantas for customised protective coatings based on alkyd resins, acrylics, epoxies, polyurethanes and silicones, solvent- or water-based coatings and UV- or moisture-curing protective coatings.

Casting resins:

Component potting is recommended for the toughest applications or extreme environmental conditions, such as offshore components. WERNER WIRTH provides one- and two-component solutions, polyurethanes and polyolefins, silicones and epoxy resins from BECTRON®.

Adhesive:

We have the right adhesive for everything – and swear by the Bectron® products from ELANTAS: from the all-rounder polyurethane to very hard epoxy resins and flexible silicones (1 & 2-component). For a versatile super adhesive, we recommend cyanoacrylate in the form of Bostik Born2Bond™.

Thermoplastics:

THERMELT’s hotmelt potting materials – polyamides and polyesters – can be moulded into any desired shape. They are suitable for connectors, sensors and whole assemblies. Permafrost or 200°C heat, salt, alcohol? No problem!

The only specialist that combines component protection and connection technology.

WERNER WIRTH combines extensive expertise, process competence, materials, components, toolmaking and machinery under one roof. Our customers regard us as a single-source specialist with a comprehensive approach to innovative connection technology and sustainable component protection. With 25 years of experience, we have developed expertise in all types of component protection – from conformal coating to potting, bonding and hotmelt moulding in all its forms.

Our experts think ahead and factor all parameters into the consultation to find the perfect solution for you. When selecting materials for perfect component protection, we consider all the decisive factors: softening point, application temperature, adhesion to the substrate, short processing times, weight, processing viscosity, Shore hardness, tensile and elongation at break, burning behaviour and resistance to aggressive media such as petrol and alcohol, as well as optimum environmental friendliness.

On request, we can also supply not only the material but also the finished coated product – or suitable production equipment, from manual systems to large-scale production modules.

Industry competence from A to Z

As the only comprehensive specialist in the electronics industry for connection technology and component protection, we provide practical, durably protected contacts on all scales in a variety of industries – from the automotive industry to point-changing systems on railways. The following list is just a small sample of our market expertise, sectors and activities. We would be delighted to discuss the polymer materials we have already supplied for challenges in your industry in a personal meeting – as well as the tools, machine technology or finished products or assemblies.

Automotive

Electromobility

Electrical and electronics

Energy systems

Medical technology

System and machine construction

Trust in the experienced specialist for electronic component protection.

PROCESSING MATERIALS

FOR ALL COMMON PROTECTION PROCESSES

25 YEARS EXPERIENCE IN

ELECTRONIC COMPONENT PROTECTION

SOUND ADVICE INCLUDED –

INDIVIDUAL & HOLISTIC

Test live: hands-on component protection.

Arrange your personal appointment now.

Would you like to meet us and experience our wide range of component protection products in person -– and test them live? Our Technology Days, which are organised specifically for you and your team, offer you the opportunity to experience everything live.

Tell us about your specific requirements, discover the wide product range and compare alternatives in practice. Please feel free to bring your own products for a sample run.

When would be the best time for a meeting?

Write to us:

Contact

Werner Wirth GmbH

Hellgrundweg 111

22525 Hamburg

Germany